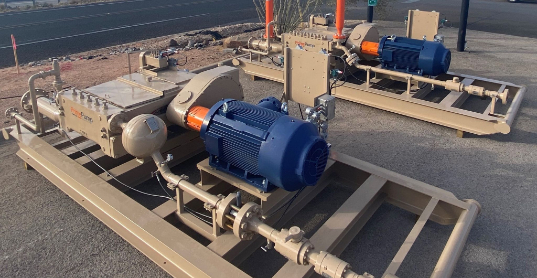

Hydraulic Jet Pumps

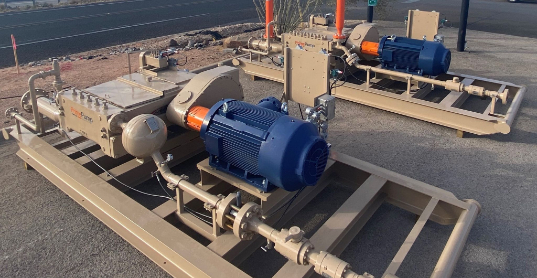

Designed to meet the most challenging well conditions, Prime Pump Solutions’ Petrolift™ hydraulic jet pumps are engineered of high-quality, anti-corrosive materials. The robust, economical design is the perfect match for high-volume wells and fluids with high solids content. With a variety of configurations and sizes, our hydraulic jet pumps for oil and gas wells are suited for operation in all types of conditions, including deviated and deep wellbores.

Engineered to exceed your expectations

Economical execution

Reliable operation

Flexible design

The Venturi effect: Why it matters

SMARTEN Jet Lift Controller

A sucker rod-drawn, positive-displacement pump that operates on the principle of pressure equalization just before the plunger reaches the top of the upstroke.

- Engineered to promote steady and consistent production, especially in gassy wells

- Industry-standard components allow the Variable Slippage™ pump to fit into nearly any well and make for a simple installation process

- Increases minimum load on the polished rod, prolonging your sucker rod life

Combines ruggedness and versatility to deliver the optimal choice for your most challenging pumping conditions.

Uses an enhanced compression ratio for efficient gas handling capabilities while moving light-to-moderate sand without sticking

Protects the pump’s critical seal components from the abrasive particles that shorten pump run life

Available in a variety of materials, surface treatments, and configurations

Designed for the most challenging rod pumping gas lock problems.

- Reduces gas locking with a compound compression ratio that can produce almost pure gas

- Versatile applications for deep or shallow wells

- Available in materials and surface treatments for abrasive and corrosive conditions

The Pampa™ gas pump increases run life in severe solids and gas conditions.

- Reduces sticking from sand or other particulates while increasing the compression ratio for fewer gas problems

- Increases run time with larger plunger and barrels wear areas

- Available in abrasion- and corrosion-resistant materials and coatings to ensure maximum product durability and life span

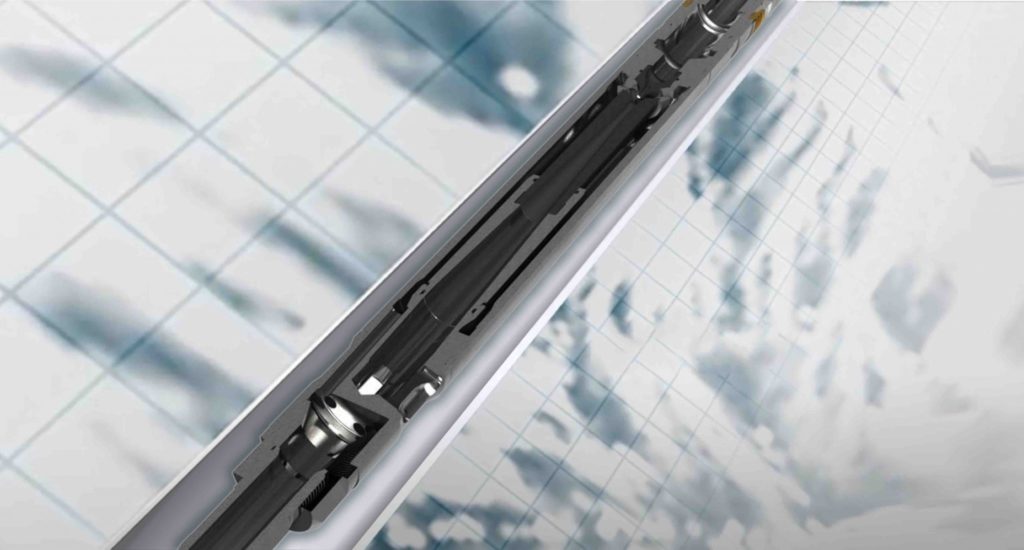

Jet pump operation

A solution for demanding production environments

The patented Sand-Pro+ pump utilizes an electroformed screen with anti-clogging capabilities that effectively restrain heavy solids from the plunger’s leading edge.

- Extends pump runtime in heavy-sand conditions

- Allows pump to run like new for longer

- Cost-effective and readily available rod pump solution for sandy wells

The patented Sand-Pro™ pump uses a unique method of separating produced sand from the pressure sealing, leading edge of the sprayed-metal plunger.

- Extends pump run times in heavy-sand conditions

- Uses mostly standard pump components to improve costs

- Available in abrasion- and corrosion-resistant materials and coatings

- Optional two-stage hollow valve rod design for gas and solids

A longer-than-normal plunger and shorter-than-normal barrel design handles sand sticking.

- Insert and tubing pump styles for all applications

- Available in optional corrosion- and abrasion-resistant materials

- Available in three configurations: Pampa tubing pump, Pampa traveling-barrel insert pump, and Pampa stationary-barrel insert pump

Designed for shallow, sandy wells that are shut down between periods of production, which often causes standard pumps to sand-up and stick.

- Sand stays in motion above the hold-down to minimize the chance of the pump being stuck in the tubing

- Incorporates an outer jacket that shields the discharge ports and forces produced fluids out of the bottom of the jacket

- Available in optional corrosion- and abrasion-resistant materials